|

|

BANKSTOWN TAFE

|

|

|

By Nick |

|

NOVEMBER 2009

|

|

SCHOOL OF ELECTRICAL ENGINEERING

|

I would like to acknowledge the help and support of the following people:

ALL THE PEOPLE AT BANKSTOWN TAFE THAT WERE ASSOCIATED WITH THE PROJECT.

THIS PROJECT WAS DESIGNED TO ALLOW STUDENTS TO PRODUCE A WORKING MODEL OF AN ELECTRIC MOTOR.

I HAVE MADE IT SIMPLE ENOUGH TO PRODUCE AND THE PROJECT ALLOWS FOR STUDENT CHANGES AND ADAPTIONS AS

REQUIRED BY THEM.

|

|

|

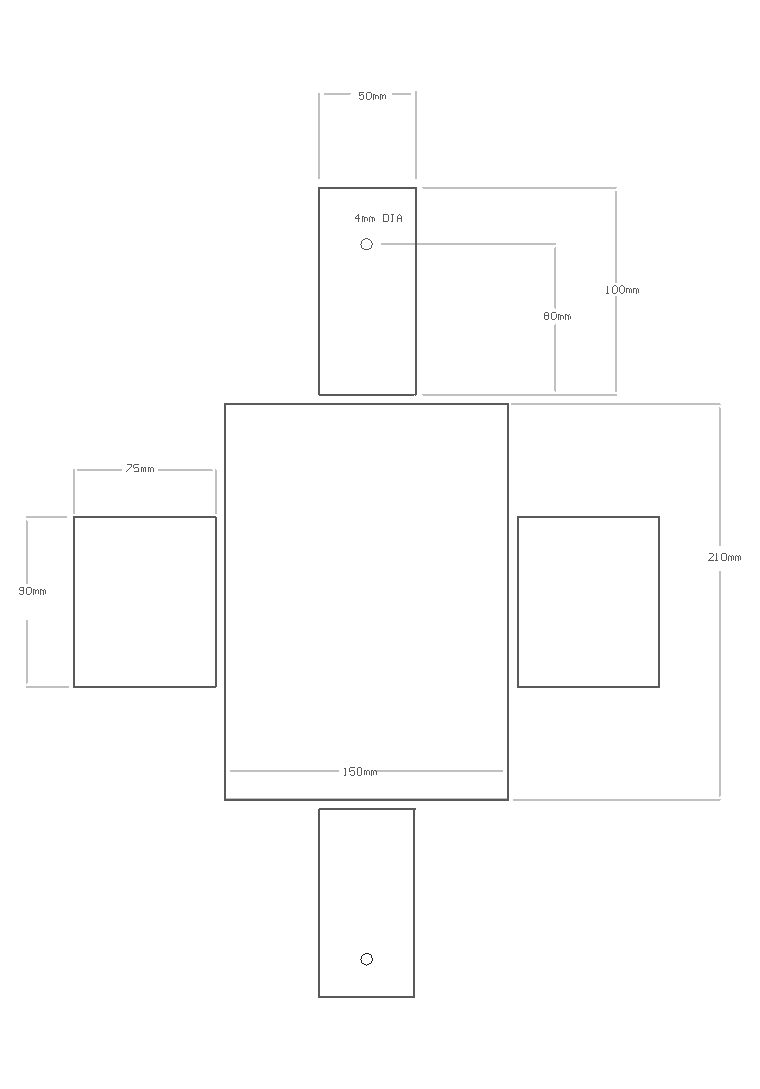

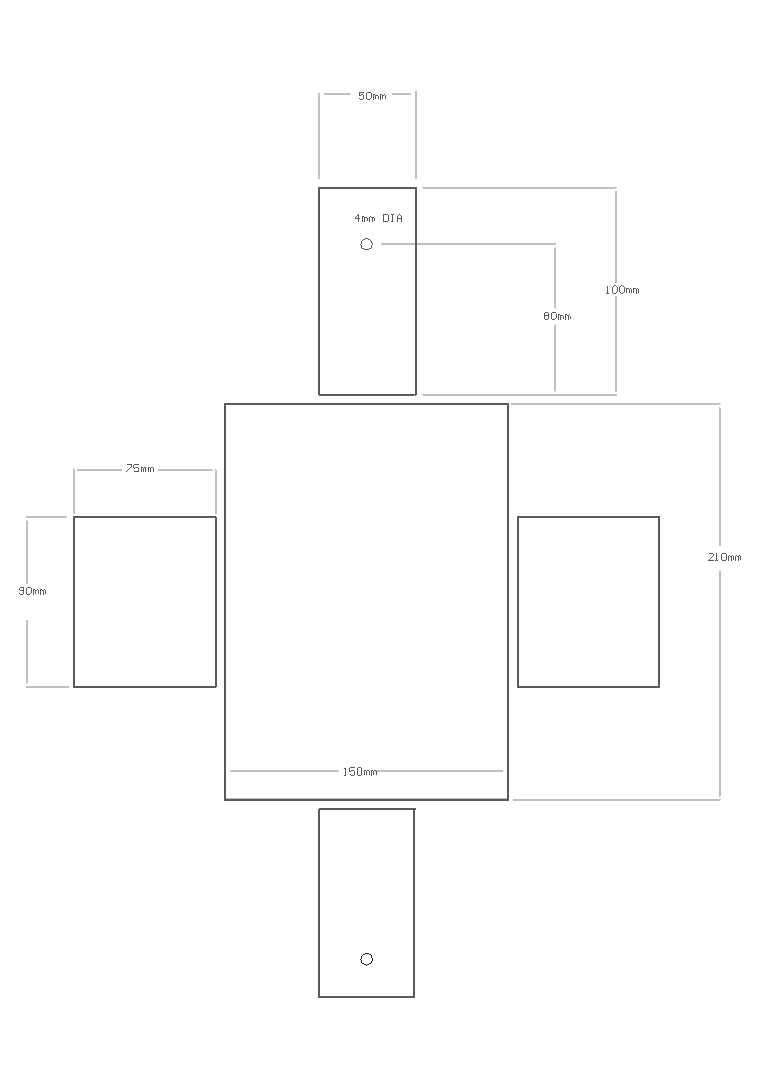

Here are the measurements of the base and end plates used in the original version.

|

PRODUCTION

|

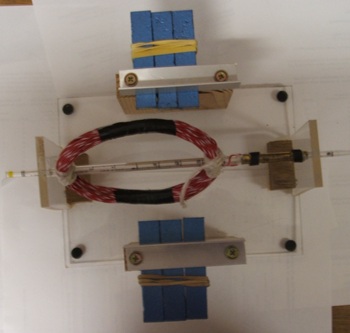

Use blocks of wood or angle pieces

To mount the ends on to the base.

|

|

|

Align the two end plates that will be used as bearings, so that the holes are straight and level. Otherwise the Pipette will bend causing friction with the glass tube.

|

|

|

Mount the magnets onto their supports. Use blocks of wood, angle pieces or any other means.

|

|

|

Using a tube or beaker approximately 100mm dia wind a coil. Keep the coil tight. Remember the more winding the more efficient it will be.

|

|

|

Remove the winding from the tube and use tape to hold it together tightly. Make it as tight as possible.

|

|

|

Cut two strips of brass or copper sheet so that it nearly covers halve the glass tube.

|

|

|

Separate some of the wire coil so that a hole appears at each end and shape the coil so it is oval or rectangular. Pass the glass tube through these holes and attach with string tightly.

|

|

|

Cut two strips of brass or copper sheet so that they nearly cover half the glass tube.

|

|

|

Cover one end of the glass tube with “Heatshrink Tubing” about the same length as the strips.

|

|

|

Solder the end of each coil to one of the brass strips

|

|

|

Mount the strips over the heatshrink tubing with more heatshrink tubing.

|

|

|

Pass the pipette through one end plate and insert the glass tube armature.

|

|