|

Here are the measurements of the base and end plates used in the original version. DOWNLOAD

|

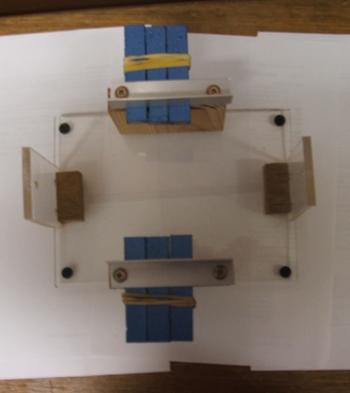

Use blocks of wood or angle pieces to mount the ends on to the

base. Secure the magnets so that the same polarity is at each end.

I used elastic bands to keep them together. Mount them on the blocks of wood making sure that the two magnetic elements have different polarity.

Align the two end plates that will be used as bearings, so that the holes are straight and level. Otherwise the Pipette will bend causing friction with the glass tube.

Mount the magnets onto their supports. Use blocks of wood, angle pieces or any other means.

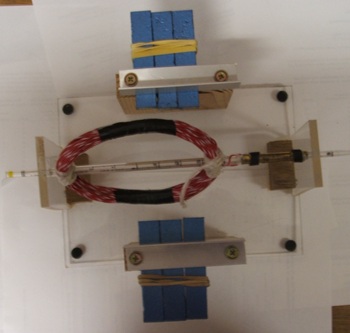

Using a tube or beaker approximately 100mm dia wind a coil. Keep the coil tight. Remember the more winding the more efficient it will be.

Remove the winding from the tube and use tape to hold it together tightly. Make it as tight as possible.

Cut two strips of brass or copper sheet so that it nearly covers halve the glass tube.

Separate some of the wire coil so that a hole appears at each end and shape the coil so it is oval or rectangular. Pass the glass tube through these holes and attach with string tightly.

Cut two strips of brass or copper sheet so that they nearly cover half the glass tube.

Cover one end of the glass tube with �Heatshrink Tubing� about the same length as the strips.

Solder the end of each coil to one of the brass strips

Mount the strips over the heatshrink tubing with more heatshrink tubing.

1. Pass the pipette through one end plate and insert the glass tube armature. Then mount it on the other end. Turn it to make sure there is no friction. If it's tight it is because the ends are not lined up straight.